The popularity of the Onyx candle jar in home decor is a perfect blend of aesthetic appeal, perceived wellness benefits, and timeless style. It's more than just a candle holder; it's a decorative statement piece.

Here’s a detailed breakdown of why it's so popular:

1. Striking Visual Aesthetics

This is the primary reason for its popularity. Onyx stone has a unique and captivating appearance that instantly elevates a space.

-

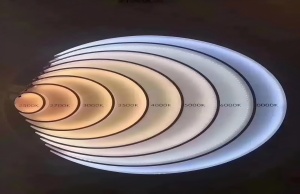

The Glow of Translucence: The magic of onyx is its semi-translucent quality. When a candle is lit inside, the entire jar glows with a warm, ambient, and almost magical light. The light dances through the natural veins and layers of the stone, creating a dynamic and organic lighting effect that a regular glass jar can't replicate.

-

Natural and Organic Texture: In an era where biophilic design (connecting with nature indoors) is a major trend, onyx brings a piece of the natural world inside. Each piece is completely unique, with its own patterns, veins, and color variations, from deep black to honey gold and green.

-

Luxurious and Sculptural: An onyx jar has a substantial, carved feel. It looks like a beautiful art object or sculpture even when the candle isn't lit. It adds a touch of organic sophistication and luxury to any shelf, mantel, or bathroom counter.

2. Versatility in Style

Onyx is surprisingly versatile and can complement a wide range of interior design styles.

-

Modern & Minimalist: Its clean lines and natural material work perfectly in a minimalist setting, acting as a stunning focal point without clutter.

-

Bohemian & Global: The raw, earthy feel of onyx fits right in with boho-chic and globally-inspired decor, adding to a collected, well-traveled vibe.

-

Traditional & Glam: The stone has been used in palaces and luxury hotels for centuries. A polished onyx jar brings an old-world, opulent feel to traditional or Hollywood Regency-style spaces.

-

Industrial: The contrast between the raw, natural stone and industrial elements like metal and concrete creates a beautifully balanced and textured look.

3. Perceived Wellness and Ambiance

The type of light an onyx jar emits is key to its appeal for creating a specific mood.

-

Soft, Ambient Lighting: The stone diffuses the candlelight, transforming a sharp flame into a soft, warm, and soothing glow. This is ideal for creating a calming, intimate, and relaxing atmosphere—perfect for unwinding after a long day, a romantic dinner, or a relaxing bath.

-

Connection to Crystal Healing: While not scientifically proven, onyx is a popular stone in crystal lore. It is often associated with properties like protection, grounding, and strength. For those who believe in or appreciate these concepts, having an onyx piece in the home adds an extra layer of intentionality and positive energy to their space.

4. Tactile and Quality Feel

Onyx stone is cool and smooth to the touch, giving it a heavy, high-quality, and substantial feel. This perceived quality is important in home decor, as people are increasingly investing in pieces that feel special and well-made, rather than disposable.

5. The "Instagrammable" Factor

The photogenic quality of a glowing onyx jar cannot be understated. It creates a beautiful, warm, and aesthetically pleasing scene that is highly sought after for social media platforms like Instagram and Pinterest. This exposure has fueled its trendiness and desirability.

In Summary:

An Onyx candle jar is popular because it successfully combines multiple desirable qualities:

-

It's a beautiful art piece when unlit.

-

It's a unique, organic light source when lit.

-

It fits into countless decor styles, from modern to boho.

-

It creates a specific, calming ambiance perfect for relaxation.

-

It feels luxurious, high-quality, and intentional.

It’s a simple yet powerful decorative object that satisfies the modern desire for natural materials, wellness-focused living, and instagrammable style.